The maximum number of products to compare is 4.

You can only compare products from the same category.

Would you like to remove all products from the comparison tool and add this one instead?

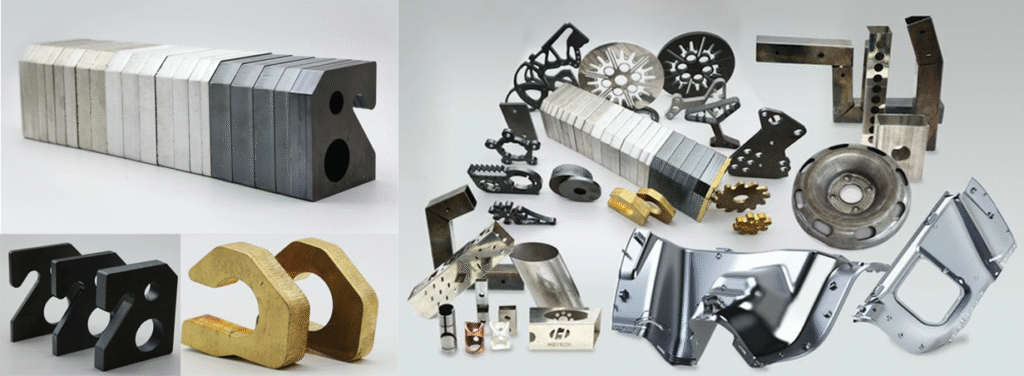

The SPARTUS Apollo 700 is a state-of-the-art 6 kW fiber laser cutter that combines immense cutting potential with the highest build quality. Its Raycus fiber laser source and intelligent Raytools BM06K cutting head ensure flawlessly smooth edges, even when processing thick materials. With fast autofocus and an efficient lens cooling system, the machine delivers continuous, stable, and highly productive operation.

At the core of the machine is a reinforced welded frame made of steel profiles, subjected to multi-stage thermal and mechanical treatment to ensure outstanding precision and durability. The crossbeam, crafted from aerospace-grade aluminum, provides both exceptional rigidity and excellent dynamic performance. The entire structure is supported by PEK guides, Atlanta precision gear racks, and Leitesen pinions—components from renowned European manufacturers.

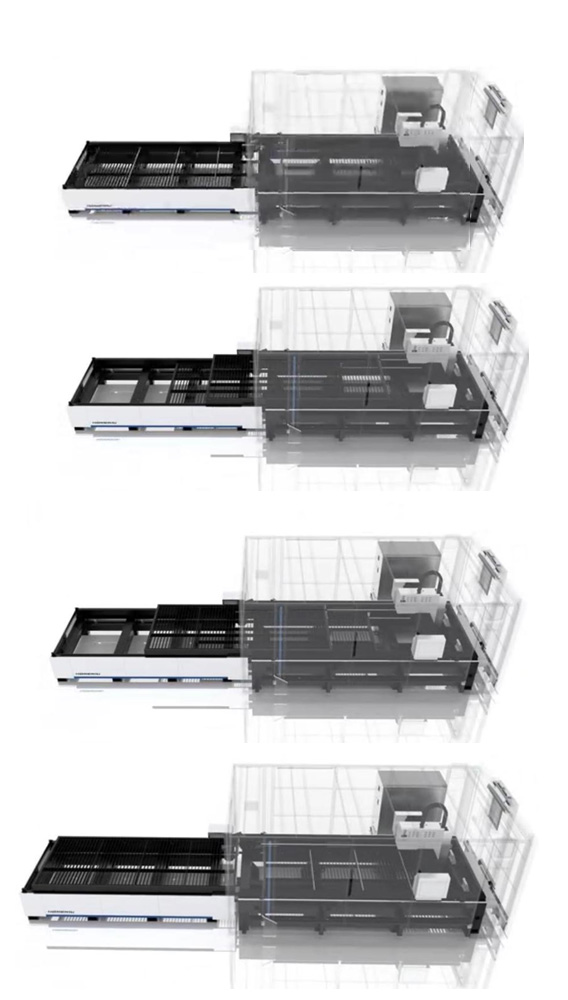

The automatic table exchange system in the SPARTUS Apollo 700 significantly enhances the efficiency of the entire cutting process. While the operator prepares the next sheet on one table, the other remains inside the machine, actively engaged in cutting. Once the operation is complete, the tables switch places in a fully automated, fast, and safe manner.

This solution eliminates downtime caused by manual material loading, increases job throughput, and ensures complete process repeatability. At the same time, the operator can prepare the next workpiece, shortening cycle times and maximizing the laser’s potential. Automation also minimizes the risk of human error and improves overall workplace safety.

The Raytools BM06K is more than just an autofocus cutting head. Equipped with an active cooling system, four protective lenses, and temperature monitoring, it ensures both safety and reliable operation. All data can be monitored in real time via a mobile application, providing effective protection of the optical system against overheating and contamination.

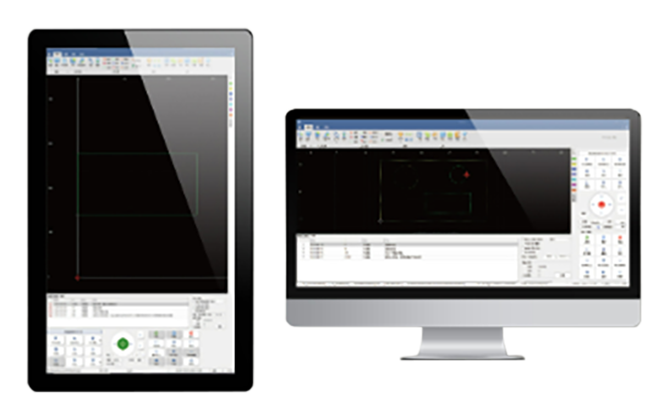

The Raytools X3S control system offers full CAD/CAM/NEST integration, enabling automatic drawing correction, cutting process optimization, and advanced production planning. Its 21-inch touchscreen provides quick access to all settings, while additional functions—such as motion error compensation and production statistics tracking—ensure repeatability and top-quality results.

The SPARTUS Apollo 700 is equipped with an 80 kVA voltage stabilizer that automatically adjusts power parameters to local grid conditions, regardless of country or region. The stabilization and regulation system protects electronics against surges and disturbances, increasing the reliability and extending the lifespan of key components.

The Apollo 700 has been designed with both ergonomics and workplace environmental protection in mind. Its enclosed structure, upper cover, and zoned fume extraction system, combined with an optional filtration and ventilation unit, ensure a clean and safe workspace in compliance with occupational safety standards. An integrated internal camera system allows monitoring of the cutting process without opening the covers, further enhancing operator safety.

The SPARTUS Apollo 700 guarantees the highest level of cutting precision through the synergy of laser power, intelligent control, and a rigid construction. Designed to meet the demands of the most challenging industries, it delivers:

| Material | Thickness [mm] | Cutting speed [m/min] | Laser power [W] | Gas | Pressure [bar] | Nozzle [mm] | Focus position [mm] | Cutting height [mm] |

|---|---|---|---|---|---|---|---|---|

| Carbon steel | 1 | 45-60 | 6000 | N₂/Air | 6.0 | 1.5S | 0.0 | 1.0 |

| Carbon steel | 2 | 35-40 | 6000 | N₂/Air | 6.0 | 2.0S | -1.0 | 0.5 |

| Carbon steel | 3 | 22-27 | 6000 | N₂/Air | 6.0 | 2.0S | -1.5 | 0.5 |

| Carbon steel | 4 | 15-20 | 6000 | N₂/Air | 8.0 | 2.0S | -2.0 | 0.5 |

| Carbon steel | 5 | 9-12 | 6000 | N₂/Air | 8.0 | 3.0S | -2.5 | 0.5 |

| Carbon steel | 6 | 8-10 | 6000 | N₂/Air | 8.0 | 3.5S | -3.0 | 0.5 |

| Carbon steel | 3 | 3.6-4.2 | 2400 | O₂ | 0.6 | 1.2E | 3.0 | 0.8 |

| Carbon steel | 4 | 3.2-3.4 | 2400 | O₂ | 0.6 | 1.2E | 3.0 | 0.8 |

| Carbon steel | 5 | 3-3.2 | 3000 | O₂ | 0.6 | 1.2E | 3.0 | 0.8 |

| Carbon steel | 6 | 2.7-2.9 | 3000 | O₂ | 0.6 | 1.2E | 3.0 | 0.8 |

| Carbon steel | 8 | 2.2-2.4 | 4500 | O₂ | 0.6 | 1.2E | 5.0 | 0.8 |

| Carbon steel | 10 | 2.0-2.2 | 6000 | O₂ | 0.6 | 1.2E | 7.0 | 0.8 |

| Carbon steel | 12 | 0.9-1 | 2400 | O₂ | 0.6 | 3.0D | 4.5 | 0.8 |

| Carbon steel | 12 | 1.9-2.1 | 6000 | O₂ | 0.6 | 1.2E | 9.0 | 0.8 |

| Carbon steel | 14 | 0.8-0.9 | 2400 | O₂ | 0.6 | 3.5D | 5.0 | 0.8 |

| Carbon steel | 14 | 1.4-1.6 | 6000 | O₂ | 0.6 | 1.4E | 12.0 | 0.8 |

| Carbon steel | 16 | 0.7-0.8 | 2400 | O₂ | 0.6 | 4.0D | 5.5 | 0.8 |

| Carbon steel | 16 | 1.2-1.4 | 6000 | O₂ | 0.6 | 1.4E | 13.0 | 0.8 |

| Carbon steel | 18 | 0.55-0.65 | 2400 | O₂ | 0.6 | 4.0D | 5.5 | 0.8 |

| Carbon steel | 18 | 0.8 | 6000 | O₂ | 0.6 | 1.4E | 13.0 | 0.3 |

| Carbon steel | 20 | 0.5-0.6 | 2400 | O₂ | 0.6 | 4.0D | 5.5 | 0.8 |

| Carbon steel | 20 | 0.6-0.8 | 6000 | O₂ | 0.75 | 1.4E | 13.5 | 0.3 |

| Carbon steel | 22 | 0.45-0.5 | 2400 | O₂ | 0.6 | 4.5D | 5.5 | 0.8 |

| Carbon steel | 22 | 0.5-0.6 | 6000 | O₂ | 0.75 | 1.5S | 13.5 | 0.3 |

| Carbon steel | 25 | 0.55 | 2700 | O₂ | 0.6 | 5.0D | 5.5 | 0.8 |

| Carbon steel | 25 | 0.4-0.5 | 6000 | O₂ | 0.75 | 1.5S | 14.0 | 0.3 |

| Carbon steel | 30 | 0.3 | 6000 | O₂ | 1.0 | 1.5S | 14.0 | 0.3 |

| Stainless steel | 1 | 45-60 | 6000 | N₂ | 10.0 | 1.5S | 0.0 | 0.8 |

| Stainless steel | 2 | 35-45 | 6000 | N₂ | 12.0 | 2.0S | -1.0 | 0.5 |

| Stainless steel | 3 | 22-27 | 6000 | N₂ | 12.0 | 2.5S | -1.5 | 0.5 |

| Stainless steel | 4 | 15-20 | 6000 | N₂ | 14.0 | 2.5S | -2.0 | 0.5 |

| Stainless steel | 5 | 9-12 | 6000 | N₂ | 14.0 | 3.0S | -2.5 | 0.5 |

| Stainless steel | 6 | 8-11 | 6000 | N₂ | 15.0 | 3.0S | -3.0 | 0.5 |

| Stainless steel | 8 | 3.5-4.5 | 6000 | N₂ | 15.0 | 3.0S | -4.0 | 0.5 |

| Stainless steel | 10 | 2-2.5 | 6000 | N₂ | 15.0 | 3.5S | -6.0 | 0.5 |

| Stainless steel | 12 | 1.5-1.8 | 6000 | N₂ | 16.0 | 3.5S | -7.5 | 0.5 |

| Stainless steel | 14 | 1-1.5 | 6000 | N₂ | 16.0 | 4.0S | -9.0 | 0.5 |

| Stainless steel | 16 | 0.5-0.6 | 6000 | N₂ | 18.0 | 4.0S | -14.0 | 0.5 |

| Stainless steel | 18 | 0.3-0.5 | 6000 | N₂ | 20.0 | 5.0S | -15.0 | 0.3 |

| Stal nierdzewna | 20 | 0.2-0.25 | 6000 | N₂ | 20.0 | 5.0S | -16.0 | 0.3 |

| Aluminium Alloy | 1 | 45-60 | 6000 | N₂ | 12.0 | 1.5S | 0.0 | 1.0 |

| Aluminium Alloy | 2 | 35-40 | 6000 | N₂ | 12.0 | 2.0S | -1.0 | 0.5 |

| Aluminium Alloy | 3 | 22-27 | 6000 | N₂ | 14.0 | 2.5S | -1.5 | 0.5 |

| Aluminium Alloy | 4 | 14-17 | 6000 | N₂ | 14.0 | 2.5S | -2.0 | 0.5 |

| Aluminium Alloy | 5 | 9-11 | 6000 | N₂ | 14.0 | 3.0S | -3.0 | 0.5 |

| Aluminium Alloy | 6 | 4-6 | 6000 | N₂ | 16.0 | 3.0S | -3.0 | 0.5 |

| Aluminium Alloy | 8 | 2.5-3 | 6000 | N₂ | 16.0 | 3.0S | -7.0 | 0.5 |

| Aluminium Alloy | 10 | 1.5-1.8 | 6000 | N₂ | 18.0 | 3.5S | -8.0 | 0.5 |

| Aluminium Alloy | 12 | 0.8-1 | 6000 | N₂ | 18.0 | 4.0S | -8.0 | 0.5 |

| Aluminium Alloy | 14 | 0.6-0.7 | 6000 | N₂ | 18.0 | 4.0S | -9.0 | 0.3 |

| Aluminium Alloy | 16 | 0.35-0.45 | 6000 | N₂ | 20.0 | 5.0S | -12.0 | 0.3 |

| Aluminium Alloy | 20 | 0.2-0.3 | 6000 | N₂ | 20.0 | 5.0S | -13.0 | 0.3 |

| Note: The parameters marked in red in the table are only for samples production, which are greatly affected by various factors in actual processing. They are only suitable for small-scale production and are not recommended for large-scale production and processing. It is recommended to use higher power lasers if need to cut thicker materials. | ||||||||

The maximum number of products to compare is 4.

You can only compare products from the same category.

Would you like to remove all products from the comparison tool and add this one instead?