The maximum number of products to compare is 4.

You can only compare products from the same category.

Would you like to remove all products from the comparison tool and add this one instead?

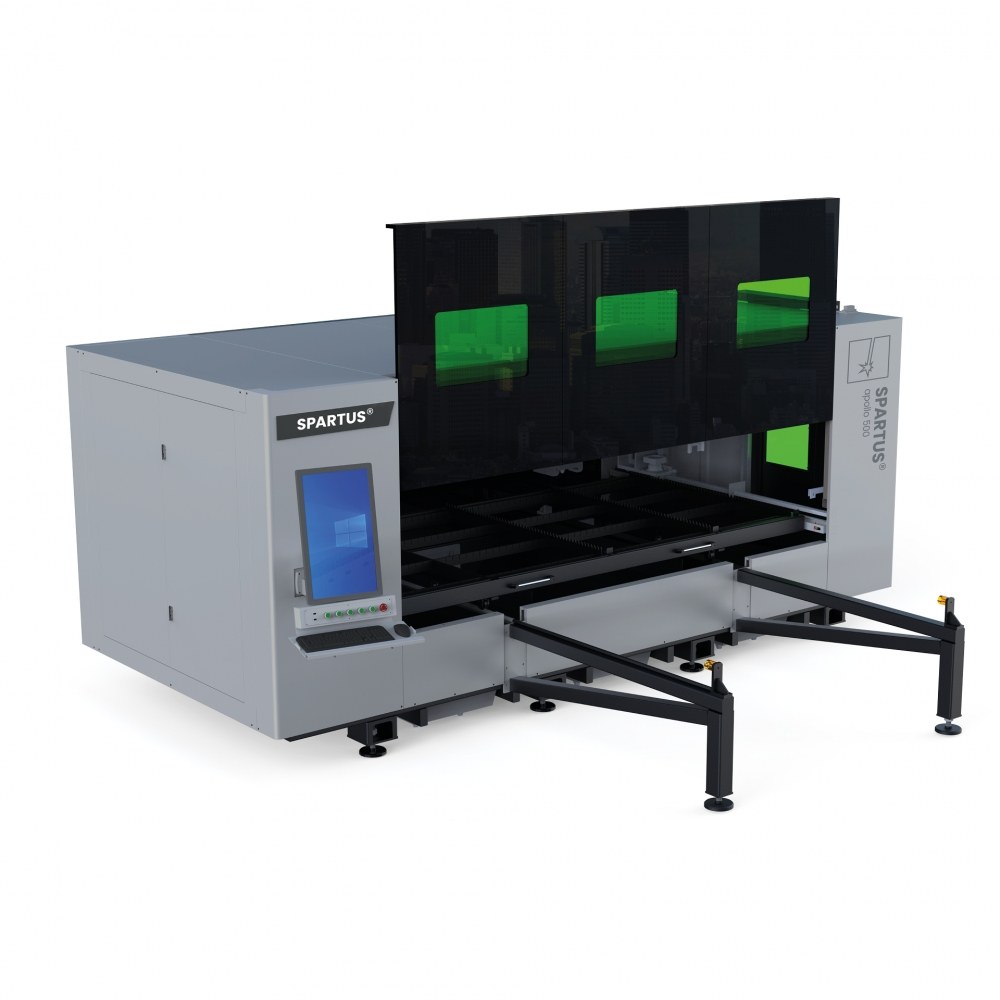

The SPARTUS Apollo 500 is a compact yet highly efficient 3 kW fiber laser cutter, designed specifically for precise sheet metal cutting. Its integrated Raycus laser source and Raytools BM110 cutting head with autofocus deliver outstanding edge quality, long service life, and stable performance even during intensive production cycles.

The Apollo 500 is built on a reinforced welded frame, subjected to thermal and mechanical treatment to ensure rigidity and resistance to vibrations. Its gantry design with a rack-and-pinion drive system offers high dynamics and precise motion control.

The crossbeam, made of cast aerospace-grade aluminum, is lightweight, distortion-resistant, and highly durable, ensuring maximum precision and long-lasting performance over years of operation.

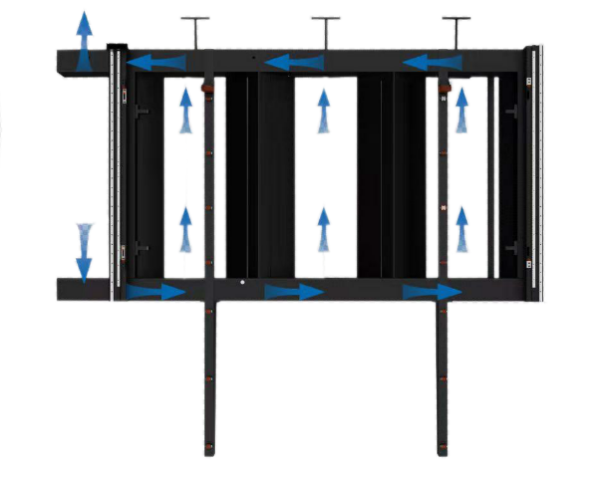

The machine features a fully enclosed design with a zoned extraction system: air is supplied on one side and removed on the other. This solution ensures effective removal of smoke and dust directly from the cutting area, protecting optical components and providing the operator with a clean and safe working environment.

The Raytools BM110 cutting head is a precision system designed to perform reliably under demanding conditions. Equipped with autofocus, an integrated cooling system, and four protective lenses, it ensures stable cutting parameters, long service life, and minimal risk of failure.

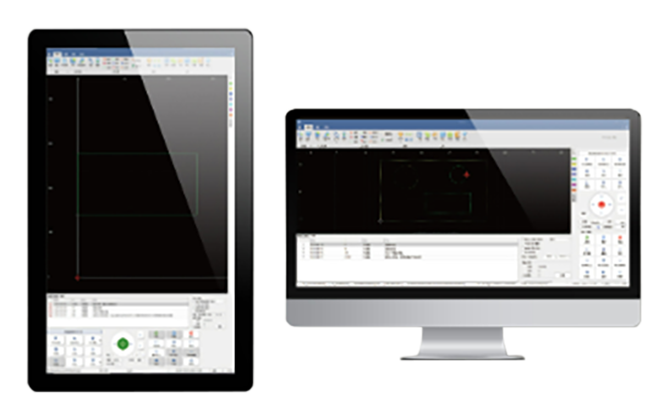

The Raytools X3S control system offers full CAD/CAM/NEST integration, enabling automatic drawing correction, cutting process optimization, and advanced production planning. Its 21-inch touchscreen provides quick access to all settings, while additional features—such as motion error compensation and production statistics tracking—ensure repeatability and the highest quality results.

The SPARTUS Apollo 500 is equipped with a 40 kVA voltage stabilizer, which plays a crucial role in ensuring safe and stable machine operation. The device automatically adjusts power parameters to local grid conditions, regardless of country or region. Its voltage stabilization and regulation functions protect electronic systems from surges and disturbances, increasing component durability and enhancing the overall reliability of the laser system.

The Apollo 500 has been designed to simplify operation to the greatest extent possible: the worktable with a side-pull function enables easy loading and unloading, while built-in features such as automatic lubrication and visual monitoring support continuous operation. High-quality components—including Schneider Electric electronics, PEK guides, Atlanta gear racks, and Leitesen pinions—ensure durability and long-term reliability.

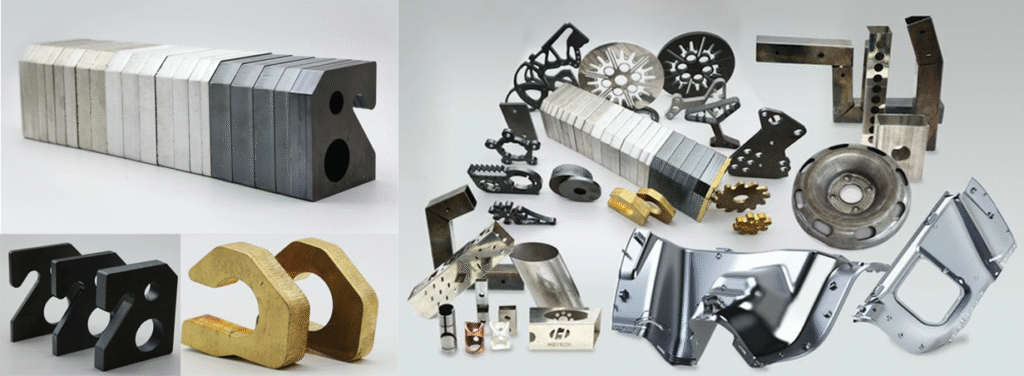

The Apollo 500 excels at cutting thin-walled components, sharp corners, and micro-holes, delivering bright, clean edges. It is a solution tailored for demanding industrial applications, where not only speed but, above all, uncompromising quality is essential.

| Material | Thickness [mm] | Cutting speed [m/min] | Laser power [W] | Gas | Pressure [bar] | Nozzle [mm] | Focus position [mm] | Cutting height [mm] |

|---|---|---|---|---|---|---|---|---|

| Carbon steel | 1 | 28-35 | 3000 | N₂/Air | 10 | 1.5S | 0 | 1 |

| Carbon steel | 2 | 16-20 | 3000 | N₂/Air | 10 | 2.0S | 0 | 0.5 |

| Carbon steel | 2 | 3.8-4.2 | 2100 | O₂ | 1.6 | 1.0D | +3 | 0.8 |

| Carbon steel | 3 | 3.2-3.6 | 2100 | O₂ | 0.6 | 1.0D | +4 | 0.8 |

| Carbon steel | 4 | 3-3.2 | 2400 | O₂ | 0.6 | 1.0D | +4 | 0.8 |

| Carbon steel | 5 | 2.7-3 | 3000 | O₂ | 0.6 | 1.2D | +4 | 0.8 |

| Carbon steel | 6 | 2.2-2.5 | 3000 | O₂ | 0.6 | 1.2D | +4 | 0.8 |

| Carbon steel | 8 | 1.8-2.2 | 3000 | O₂ | 0.6 | 1.2D | +4 | 0.8 |

| Carbon steel | 10 | 1-1.3 | 3000 | O₂ | 0.6 | 1.2D | +4 | 0.8 |

| Carbon steel | 12 | 0.9-1 | 2400 | O₂ | 0.6 | 3.0D | +4 | 0.8 |

| Carbon steel | 14 | 0.8-0.9 | 2400 | O₂ | 0.6 | 3.0D | +4 | 0.8 |

| Carbon steel | 16 | 0.6-0.7 | 2400 | O₂ | 0.6 | 3.5D | +4 | 0.8 |

| Carbon steel | 18 | 0.5-0.6 | 2400 | O₂ | 0.6 | 4.0D | +4 | 0.8 |

| Carbon steel | 20 | 0.4-0.55 | 2400 | O₂ | 0.6 | 4.0D | +4 | 0.8 |

| Carbon steel | 22 | 0.45-0.5 | 2400 | O₂ | 0.6 | 4.0D | +4 | 0.8 |

| Stainless steel | 1 | 28-35 | 3000 | N₂ | 10 | 1.5S | 0 | 0.8 |

| Stainless steel | 2 | 18-24 | 3000 | N₂ | 12 | 2.0S | 0 | 0.5 |

| Stainless steel | 3 | 7-10 | 3000 | N₂ | 12 | 2.5S | -0.5 | 0.5 |

| Stainless steel | 4 | 5-6.5 | 3000 | N₂ | 14 | 2.5S | -1.5 | 0.5 |

| Stainless steel | 5 | 3-3.6 | 3000 | N₂ | 14 | 3.0S | -2.5 | 0.5 |

| Stainless steel | 6 | 2-2.7 | 3000 | N₂ | 14 | 3.0S | -3 | 0.5 |

| Stainless steel | 8 | 1-1.2 | 3000 | N₂ | 16 | 3.5S | -4.5 | 0.5 |

| Stainless steel | 10 | 0.5-0.6 | 3000 | N₂ | 16 | 4.0S | -6 | 0.5 |

| Aluminum | 1 | 25-30 | 3000 | N₂ | 12 | 1.5S | 0 | 0.8 |

| Aluminum | 2 | 15-18 | 3000 | N₂ | 12 | 2.0S | 0 | 0.5 |

| Aluminum | 3 | 7-8 | 3000 | N₂ | 14 | 2.0S | -1 | 0.5 |

| Aluminum | 4 | 5-6 | 3000 | N₂ | 14 | 2.5S | -2 | 0.5 |

| Aluminum | 5 | 2.5-3 | 3000 | N₂ | 16 | 3.0S | -3 | 0.5 |

| Aluminum | 6 | 1.5-2 | 3000 | N₂ | 16 | 3.0S | -3.5 | 0.5 |

| Aluminum | 8 | 0.6-0.7 | 3000 | N₂ | 16 | 3.5S | -4 | 0.5 |

The maximum number of products to compare is 4.

You can only compare products from the same category.

Would you like to remove all products from the comparison tool and add this one instead?