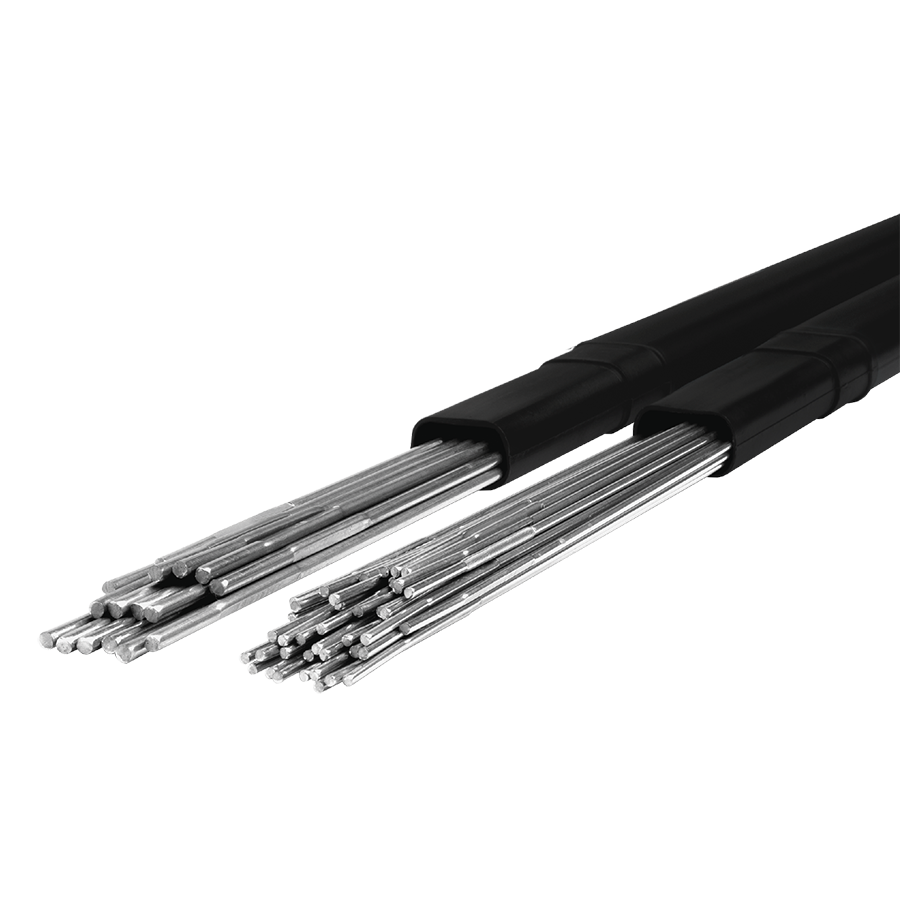

Welding rods for steel

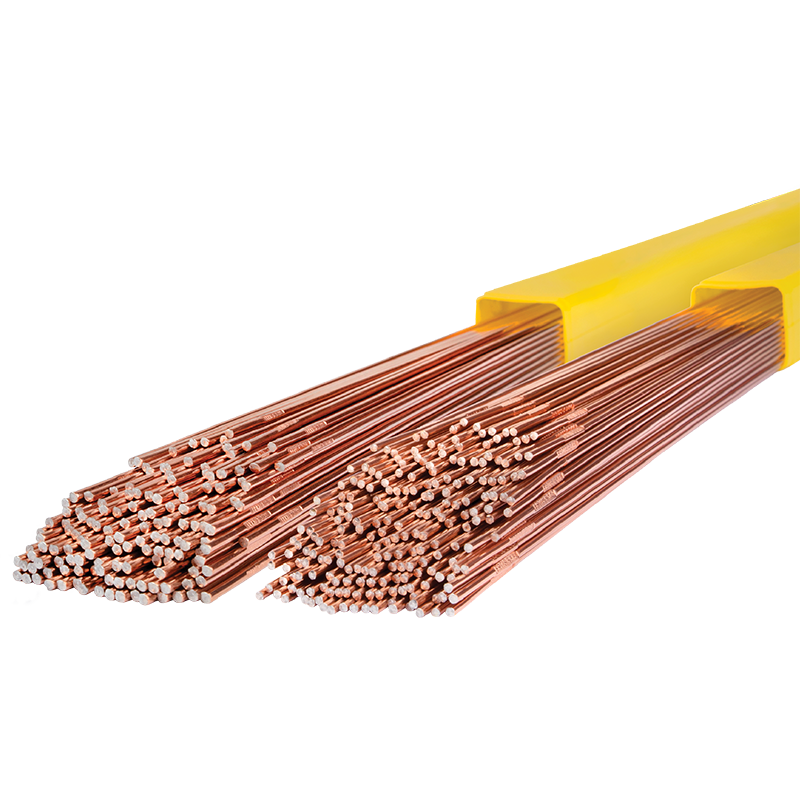

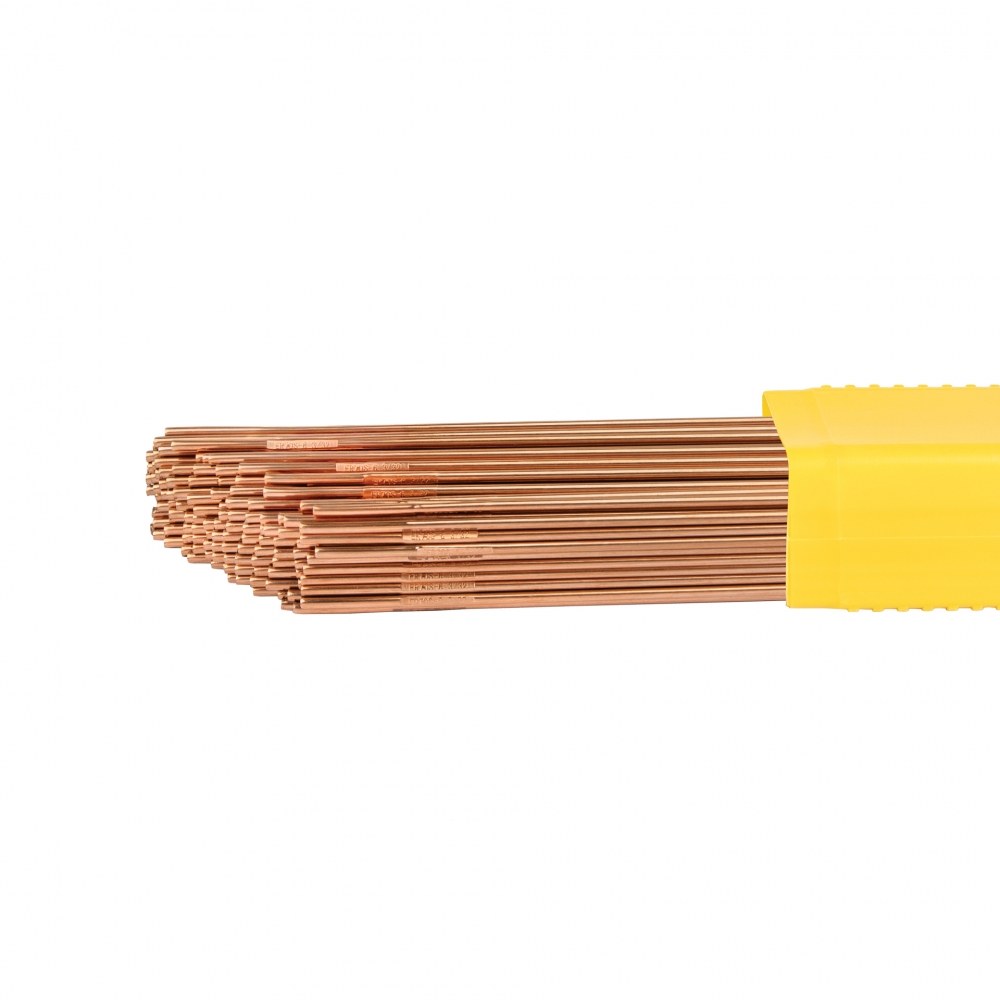

Welding Rod SPARTUS ER70S-6 [SG2]

Copper-coated welding rod ER70S-6 with added manganese and silicon is the ideal product for welding unalloyed steel, fine-grained steel, and pipes. It is particularly recommended for applications requiring precision and durability.

SPARTUS ER70S-6 welding rod offers above all:

- Reduced slag formation – cleaner welding process and less post-weld treatment required.

- Smooth weld deposit – ensures aesthetic and durable joints.

- Copper coating – thin and uniform, increases corrosion resistance and extends product lifespan.

- Versatility – suitable for welding various materials and structures.

The wire finds wide application in many industries:

- Welding galvanized and pre-painted steel – excellent for processing coated materials.

- Pipeline, boiler, and tank production – suitable for low-alloy steels.

- Pipe connections in chemical, petrochemical, water, and gas industries – ideal for root passes and finishing welds.

- Welding thin sheet metals – precise joints with minimal distortion.

- Welding repairs – effective in the regeneration and maintenance of metal components.

Standards:

EN 13479

EN ISO 14341-A-G 3Si1

AWS A5.18 ER70S-6

Approvals: TÜV

| ROD DIAMETER |  5kg TUBE |

|---|---|

| 1.6mm | ER70S-6-16-500 |

| 2.0mm | ER70S-6-20-500 |

| 2.4mm | ER70S-6-24-500 |

| 3.2mm | ER70S-6-32-500 |

Welding rods for stainless steel

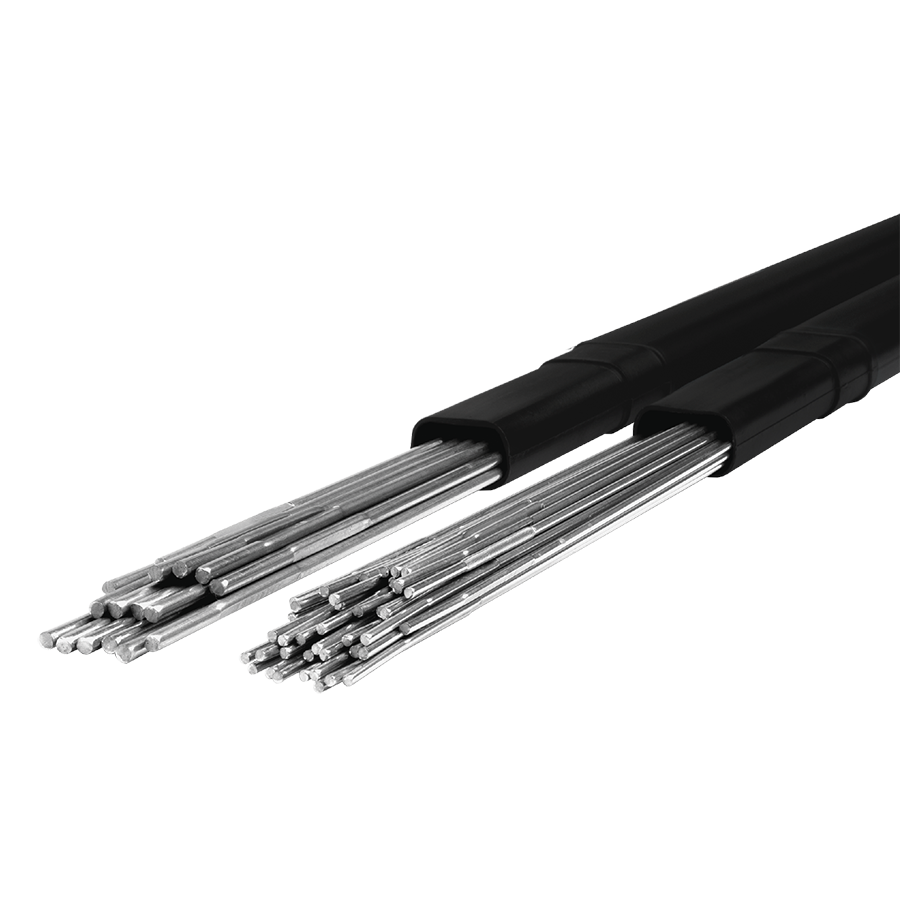

Welding Rod SPARTUS 308LSi

SPARTUS 308LSi is a high-quality TIG welding rod made of stainless steel, ideal for welding austenitic stainless steels. Thanks to its excellent properties, it is indispensable in many industrial applications.

Key properties:

- Excellent corrosion resistance – ensures durable and reliable joints.

- High mechanical strength – provides strong and aesthetic welds.

- Versatility – suitable for various grades of austenitic stainless steels.

Applications:

- Welding 18%Cr / 8%Ni stainless steels – including grades such as AISI 304, 304L, and 308LSi.

- Industrial projects – an excellent choice for welding components requiring high corrosion resistance and durability.

Standards:

EN 13479

EN ISO 14343-A-W 19 9 LSi

AWS A5.9 / ASME SFA5.9 ER 308LSi

Approvals: TÜV, DB

| ROD DIAMETER |  1kg TUBE |  5kg TUBE |

|---|---|---|

| 1.0mm | T-308LSI-10-100 | T-308LSI-10-500 |

| 1.2mm | T-308LSI-12-100 | T-308LSI-12-500 |

| 1.6mm | T-308LSI-16-100 | T-308LSI-16-500 |

| 2.0mm | T-308LSI-20-100 | T-308LSI-20-500 |

| 2.4mm | T-308LSI-24-100 | T-308LSI-24-500 |

| 3.2mm | T-308LSI-32-100 | T-308LSI-32-500 |

Welding rod SPARTUS ER316LSi

SPARTUS 316LSi is a high-quality TIG welding rod made of stainless steel with very low carbon content.

This product is an excellent choice for precise welding tasks and for overlaying components with a similar chemical composition.

Key features:

- Low carbon content – ensures high resistance to intergranular corrosion.

- Professional chemical composition – guarantees durable and aesthetic welds.

- Versatility – suitable for a wide range of industrial applications.

Applications:

- Welding stainless steels – ideal for materials with a chemical composition close to ER 316LSi.

- Surface overlaying – effective in creating protective layers on steel components.

Standards:

EN 13479

EN ISO 14343-A-W 19 12 3 LSi

AWS A5.9 / ASME SFA5.9 ER 316LSi

Approvals: TÜV, DB

| ROD DIAMETER |  1kg TUBE |  5kg TUBE |

|---|---|---|

| 1.0mm | T-316LSI-10-100 | T-316LSI-10-500 |

| 1.2mm | T-316LSI-12-100 | T-316LSI-12-500 |

| 1.6mm | T-316LSI-16-100 | T-316LSI-16-500 |

| 2.0mm | T-316LSI-20-100 | T-316LSI-20-500 |

| 2.4mm | T-316LSI-24-100 | T-316LSI-24-500 |

| 3.2mm | T-316LSI-32-100 | T-316LSI-32-500 |

Welding rod SPARTUS ER309LSi

SPARTUS 309LSi is a high-quality TIG stainless steel welding rod. Designed for welding various steel alloys and austenitic steels, it performs exceptionally well in demanding industrial applications.

Key properties:

- Versatility – suitable for a wide range of industrial applications.

- Durability and precision – ensures strong, aesthetic, and corrosion-resistant welds.

Applications:

- Welding of austenitic stainless steels – ideal for AISI 309LSi steel.

- Joining steels – reliable for connecting materials with different properties.

- Intermediate and build-up layers – dedicated for work on 18%Cr / 8%Ni type steels.

Standards:

EN 13479

EN ISO 14343-A-W 23 12 LSi

AWS A5.9 / ASME SFA5.9 ER 309LSi

Approvals: TÜV, DB

| ROD DIAMETER |  1kg TUBE |  5kg TUBE |

|---|---|---|

| 1.0mm | T-309LSI-10-100 | T-309LSI-10-500 |

| 1.2mm | T-309LSI-12-100 | T-309LSI-12-500 |

| 1.6mm | T-309LSI-16-100 | T-309LSI-16-500 |

| 2.0mm | T-309LSI-20-100 | T-309LSI-20-500 |

| 2.4mm | T-309LSI-24-100 | T-309LSI-24-500 |

| 3.2mm | T-309LSI-32-100 | T-309LSI-32-500 |

Welding rods foR aluminum

Welding rod SPARTUS AlMg4,5Mn ER5183

SPARTUS AlMg4.5Mn ER5183 welding rod is a high-class product designed for welding magnesium-aluminum alloys from the 5000 series. Thanks to its excellent mechanical properties and high corrosion resistance, it is a reliable choice for the most demanding industrial applications.

Advantages:

- Reliability in harsh conditions – excellent resistance to atmospheric factors.

- Versatile applications – from marine structures to industrial use.

- Professional weld quality – precise and durable joints in demanding projects.

Key features:

- High magnesium content – provides high mechanical strength and corrosion resistance.

- Corrosion resistance – ideal for use in marine and humid environments.

- Smooth and aesthetic welds – ensures a professional appearance and long-lasting joints.

- Stable welding process – enables precise control during TIG welding.

Applications:

- Welding aluminum-magnesium alloys – especially recommended for high-magnesium alloys such as 5083 and 5654.

- Marine constructions – ideal for welding components exposed to seawater and harsh weather conditions.

- Industrial production – widely used in shipbuilding, construction, transportation, and pressure vessel manufacturing.

- Repair of aluminum structures – an excellent choice for repairs requiring high strength and durability.

- Professional weld quality – precise and long-lasting joints in demanding projects.

Standards:

EN 13479

EN ISO 18273-S Al 5183

SFA/AWS A5.10:R5183

Approvals: DB

| ROD DIAMETER |  2.5kg TUBE |

|---|---|

| 1.6mm | T-5183-16-250 |

| 2.0mm | T-5183-20-250 |

| 2.4mm | T-5183-24-250 |

| 3.2mm | T-5183-32-250 |

Welding rod SPARTUS AlMg5 ER5356

SPARTUS AlMg5 ER5356 welding rod is a top-quality product designed for welding aluminum alloys containing magnesium. Thanks to its excellent mechanical properties and high corrosion resistance, this rod is perfectly suited for a wide range of industrial and structural applications.

Advantages:

- Professional weld quality.

- Easy application and stable welding arc.

- Ideal for demanding aluminum projects and constructions.

Key features:

- High magnesium content – ensures high mechanical strength and corrosion resistance.

- Aesthetic welds – smooth and durable joints, perfect for projects requiring premium finish quality.

- Resistance to harsh conditions – performs exceptionally well in corrosive environments, especially in the marine industry.

Applications:

- Welding aluminum-magnesium alloys – excellent for welding 5000 series alloys.

- Corrosion-exposed structures – ideal for use in marine and humid environments.

- Industrial production – used in construction, automotive, shipbuilding, and aerospace industries.

- Repairs and modifications of aluminum structures – reliable for projects requiring precision and durability.

Standards:

EN 13479

EN ISO 18273-S Al 5356

SFA/AWS A5.10:ER5356

Approvals: DB

| ROD DIAMETER |  2.5kg TUBE |

|---|---|

| 1.6mm | T-5356-16-250 |

| 2.0mm | T-5356-20-250 |

| 2.4mm | T-5356-24-250 |

| 3.2mm | T-5356-32-250 |

Welding rod AlSi5 ER4043

SPARTUS AlSi5 ER4043 welding rod is a high-quality product designed for welding aluminum alloys containing silicon. Its excellent mechanical properties and resistance to cracking make it an ideal choice for a wide range of industrial and repair applications.

Advantages:

- Professional weld quality for the most demanding projects.

- Versatile applications – from production to repair.

- Reliability in harsh environmental conditions.

Key features:

- Silicon content – increases resistance to cracking and improves the mechanical properties of welds.

- Aesthetic welds – creates smooth and precise joints, perfect for projects requiring a high-quality finish.

- Easy application – ensures a stable welding arc and excellent control of the welding process.

- Corrosion resistance – suitable for structures operating in harsh atmospheric conditions.

Applications:

- Welding aluminum-silicon alloys – excellent for materials from the 4000 and 6000 series.

- Industrial production – used in automotive, construction, aerospace, and shipbuilding industries.

- Structures exposed to harsh conditions – ensures durable and corrosion-resistant joints.

- Repairs and refurbishments – ideal for repairing aluminum components.

Standards:

EN 13479

EN ISO 18273-S Al 4043A

SFA/AWS A5.10:R4043

Approvals: DB

| ROD DIAMETER |  2.5kg TUBE |

|---|---|

| 1.6mm | T-4043-16-250 |

| 2.0mm | T-4043-20-250 |

| 2.4mm | T-4043-24-250 |

| 3.2mm | T-4043-32-250 |