SPARTUS MAXIMUS D16 – precision and durability you can rely on.

The SPARTUS MAXIMUS D16 welding tables are solutions designed for professional applications in the metalworking industry. Made of high-strength nitrided S355J2+N steel and equipped with a Ø16 mm mounting hole system, they provide a solid and precise base for welding, assembly, and workshop operations.

Nitrided surface – durability that makes a difference

It is the nitrided surface of the SPARTUS MAXIMUS D16 tables that set them apart from the competition. Thanks to the nitriding process, the S355J2+N steel gains exceptional resistance to wear, corrosion, and high temperatures. Precision machining ensures a surface flatness accuracy of 0.1 mm/㎡, delivering perfectly even work areas – even under heavy loads. These solutions guarantee full stability during part positioning and maximum welding accuracy – regardless of the size of the structures.

The 12–14 mm thick tops offer an ideal balance between massiveness and precision. This well-chosen design ensures resistance to impacts, high temperatures, and deformation, maintaining perfect flatness for years of operation.

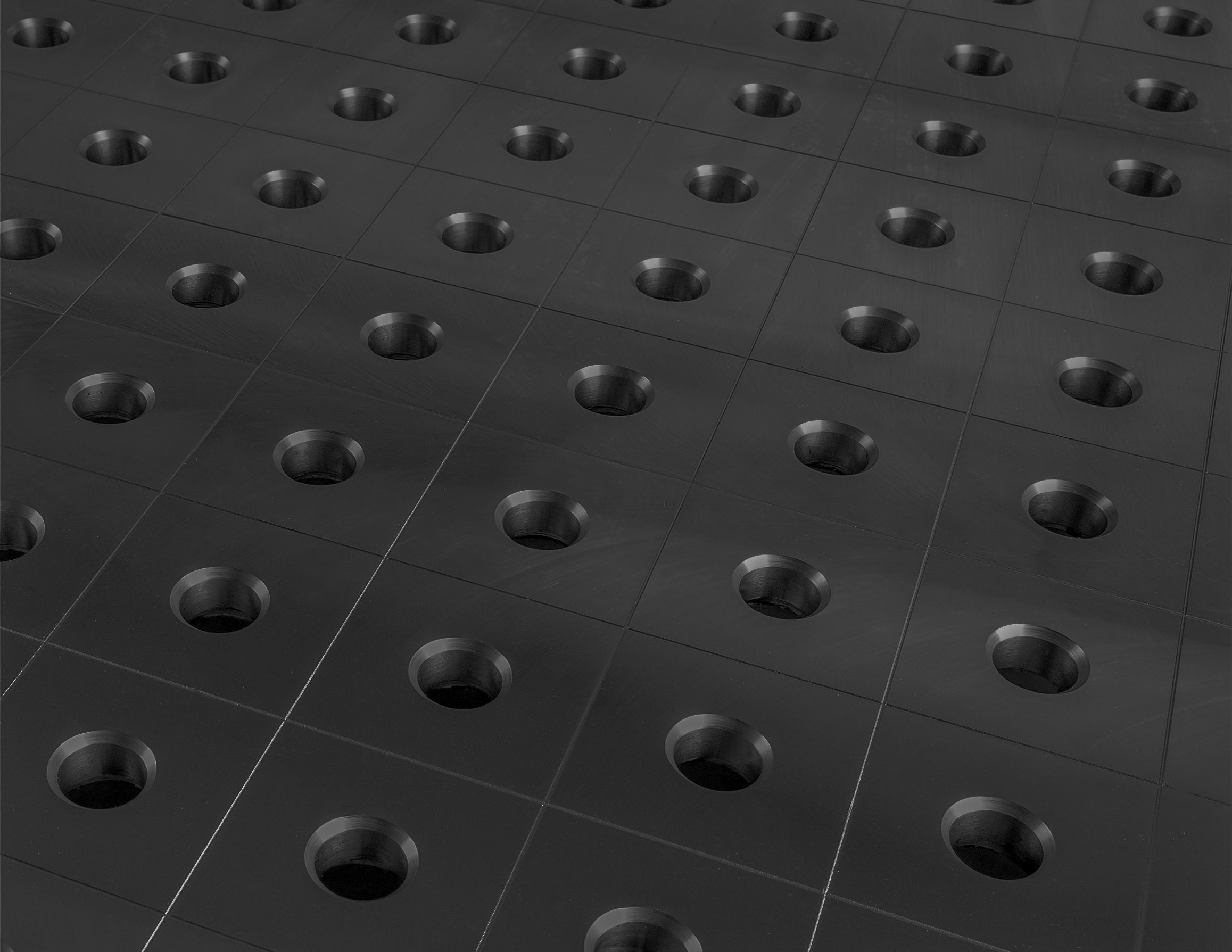

Drilled and milled Ø16 mm hole system

The working surface is equipped with precisely drilled and milled holes with a diameter of 16 mm, arranged in the regular D16 system layout. Each hole is made with an accuracy of +0.05 mm, and the hole spacing is 50 mm.

This high level of precision ensures full compatibility with system accessories and enables fast, repeatable, and stable clamping using clamps, angles, and stops.

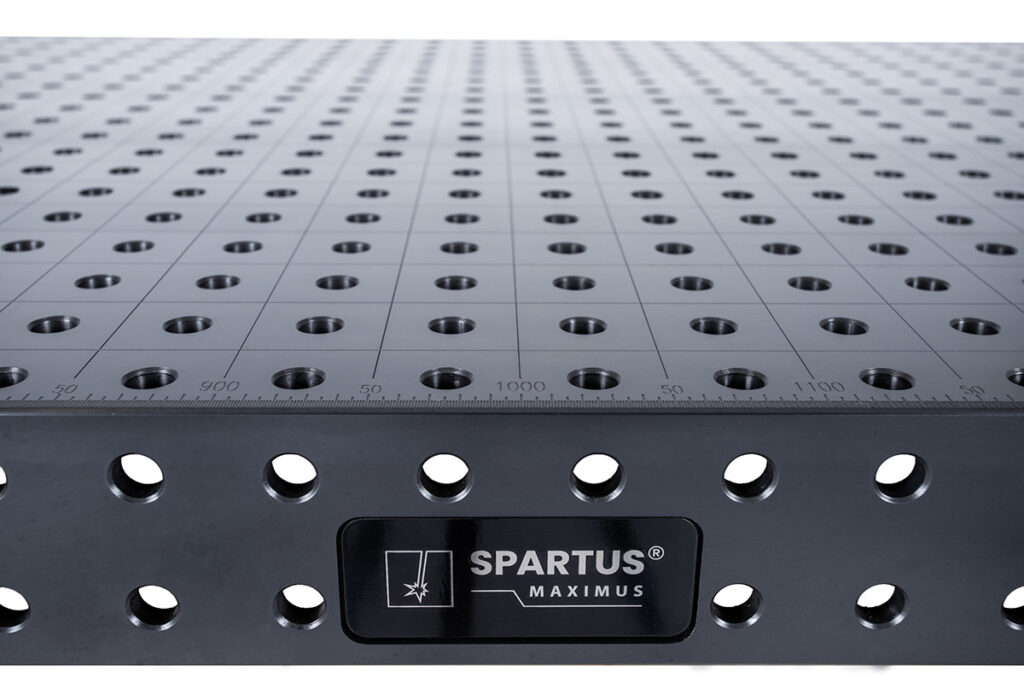

Millimeter scale – fast and accurate positioningcjonowanie

The working surface features a clear millimeter scale that makes it easier to precisely position workpieces and fixtures. This practical tool increases repeatability and shortens setup time.

3D modular side – flexible workstation configuration

The SPARTUS MAXIMUS D16 table is based on a 3D modular side system, which allows the working area to be expanded in any direction. This makes it easy to increase the workspace or adapt the table layout to the needs of a specific project – from precise components to large steel structures.

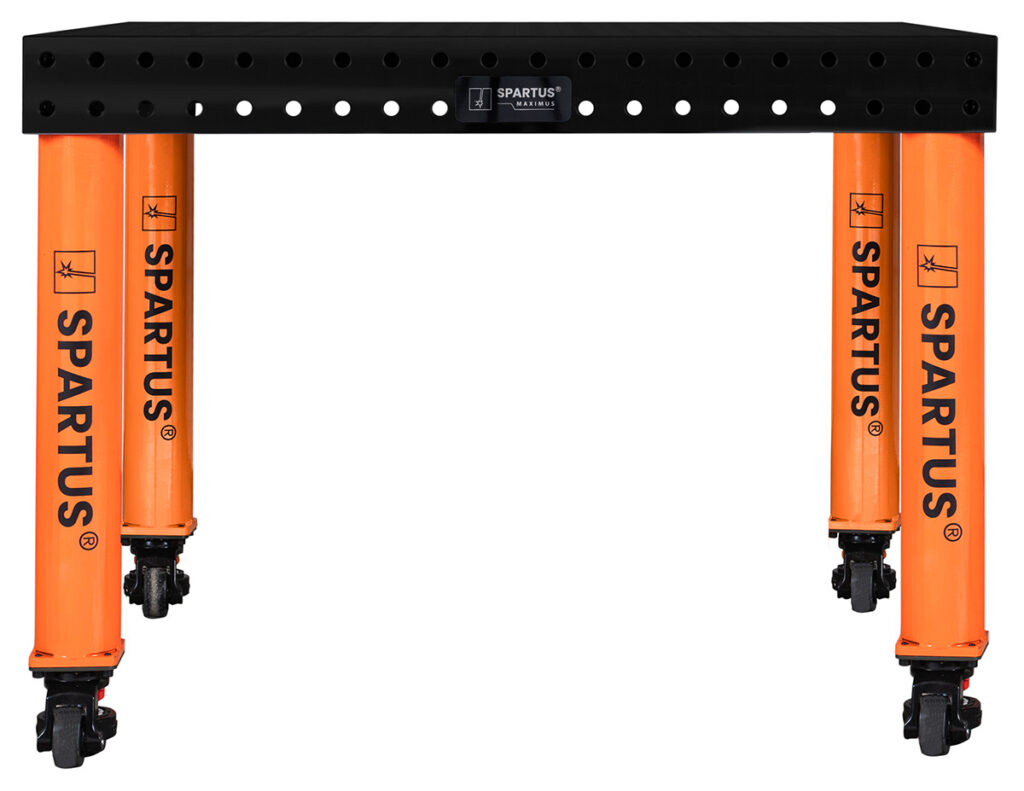

Stable D16 table legs with wheels and brakes – five height options

SPARTUS D16 welding tables are available with legs in five height variants, allowing optimal adjustment to the type of work performed.

| Leg Length | Table Height |

|---|---|

| 730mm | 830mm |

| 650mm | 750mm |

| 450mm | 550mm |

| 350mm | 450mm |

| 200mm | 300mm |

SPARTUS D16 welding tables are equipped with legs featuring a wheel system and integrated parking brake, allowing easy repositioning of the table within the workspace.

Once positioned, the mechanical brake with rotation and movement lock enables the table to be securely “parked,” ensuring full structural rigidity during welding.

This solution combines mobility with user safety, enabling the table to be moved freely and then quickly locked in the working position.

Applications of SPARTUS D16 welding tables

SPARTUS D16 welding tables are used in:

- structural welding,

- steel component assembly and machining,

- production workshops,

- assembly lines,

- training and educational facilities.

SPARTUS D16 – the precision base for your work

By choosing a SPARTUS welding table in the D16 system, you invest in accuracy, durability, and reliability. It’s a solution that enhances every stage of the welding and assembly process, ensuring repeatability and the highest comfort of work.

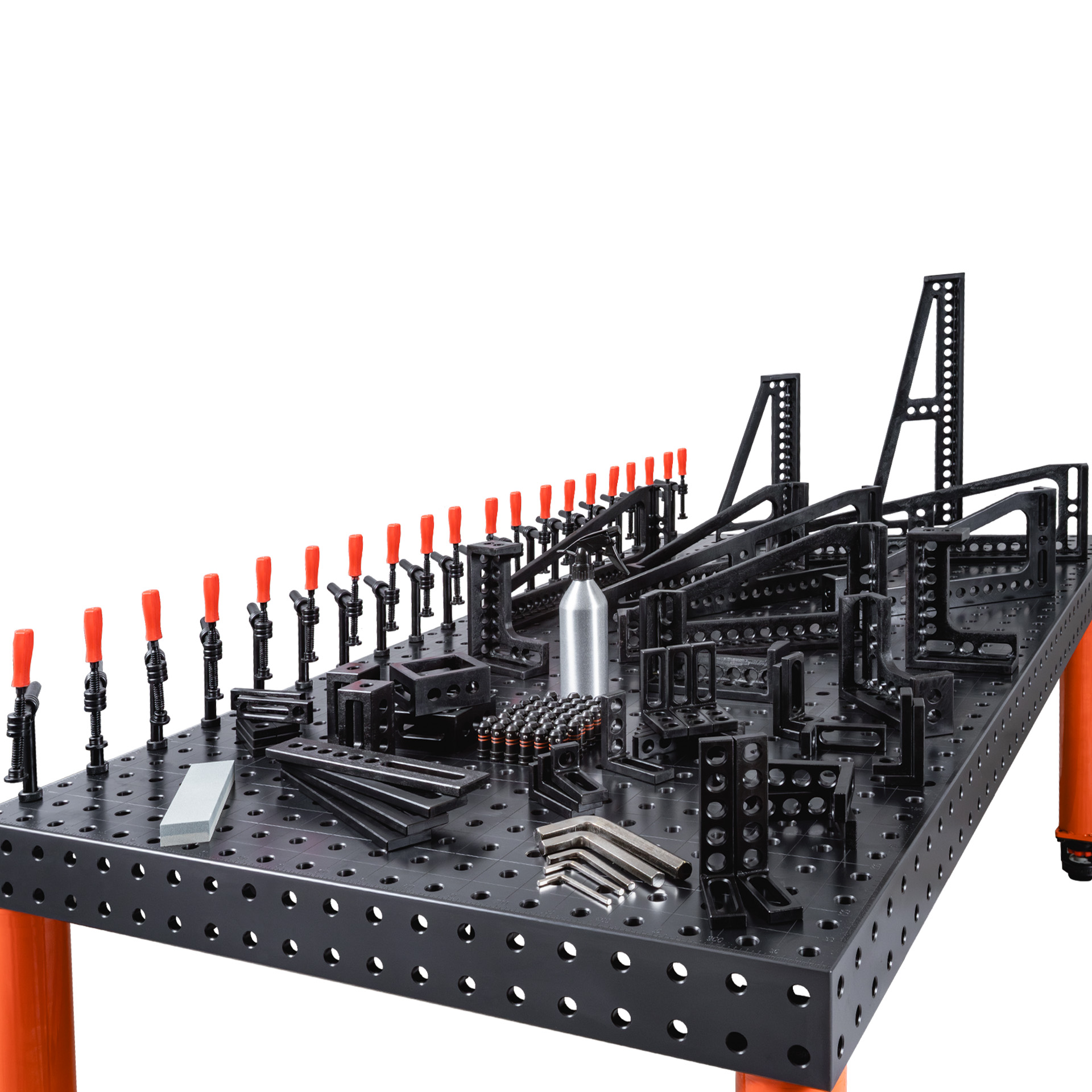

Accessories for SPARTUS D16 welding tables

SPARTUS offers a wide range of accessories for D16 welding tables that allow you to fully utilize your workstation’s potential. We offer both individual components and complete accessory kits tailored to user needs. The range includes welding clamps, angle brackets, prisms, locating pins, sockets, stoppers, and clamping blocks – all compatible with the D16 hole system. With these accessories, you can easily and precisely secure workpieces, expand your working area, and increase accuracy and efficiency when working with the SPARTUS D16 table.

Technical details

| Size of the work surface | 2000x1000x100mm | 2000x1200x100mm |

| Made | welded with a protective coating (nitrided) | welded with a protective coating (nitrided) |

| Material | S355J2+N steel acc. to EN 10025-2 | S355J2+N steel acc. to EN 10025-2 |

| Table top thickness | 12-14mm | 12-14mm |

| Table horizontal precision | 0.1 mm/m² | 0.1 mm/m² |

| Standard | D16 (drilled and milled holes 16mm diameter) | D16 (drilled and milled holes 16mm diameter) |

| Carrying capacity | 2000kg | 2000kg |

| Number of legs | 4pcs. | 6pcs. |

| Jack weight | 280kg | 380kg |