The maximum number of products to compare is 4.

You can only compare products from the same category.

Would you like to remove all products from the comparison tool and add this one instead?

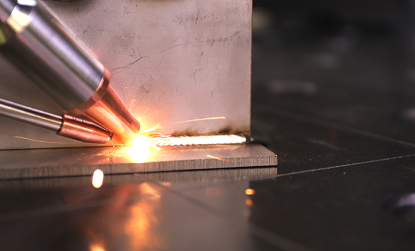

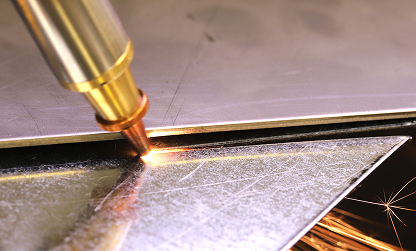

The SPARTUS Easy 3000 Laser Welder is the key to achieving joints of unmatched quality.

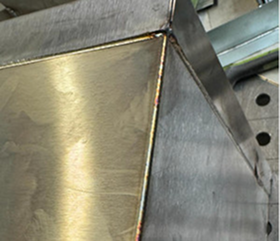

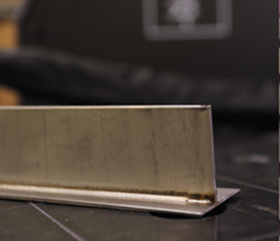

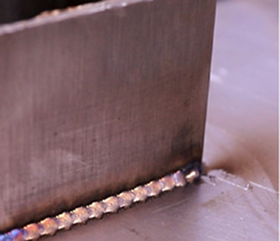

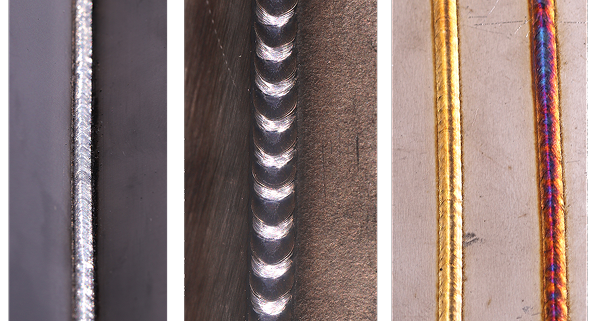

Powered by a high-class Raycus laser source, the device surpasses traditional welding methods such as MIG or TIG thanks to the exceptional precision it offers. The applied technology enables the creation of much smaller, microscopic welds, minimizing the heat-affected zone on the surrounding material. As a result, laser welding is the perfect choice for joining even very small components that are difficult to weld using other methods.

High precision

Excellent control of the welding process

Clean welds that require no post-cleaning

Minimal distortions

Durable and strong joints

Optimized production time

Laser welding surpasses traditional methods such as MIG or TIG, thanks to its exceptional precision and the ability to produce significantly smaller, microscopic welds.

This process minimizes the heat-affected zone on the material, preserving its properties and preventing deformations. As a result, laser technology is the ideal solution for joining even the smallest components that are difficult to weld using other methods

| Stainless steel | 8mm |

| Galvanized sheet | 6mm |

| Iron | 8mm |

| Mild steel | 8mm |

| Aluminum | 5mm |

| Brass | 4mm |

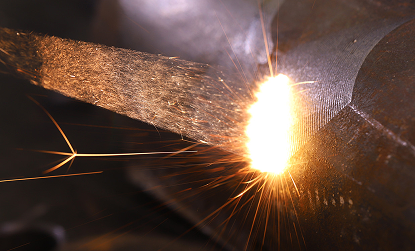

Laser welding is a technology that enables the creation of durable and aesthetic metal joints. The concentrated light beam makes it possible to achieve high-quality welds without the risk of deformation or changes in the material structure. This method is ideal for working with thin components and alloys with a high melting point. Thanks to the repeatability and stability of the process, laser welding is widely used in production that requires the highest precision.w produkcji wymagającej najwyższej dokładności.

Laser cutting is a method that ensures precise shapes and smooth edges without the need for additional processing. The laser beam enables highly accurate cutting while minimizing heat influence and reducing the risk of distortions. This solution helps reduce waste and fully utilize the material, resulting in significant savings of raw resources. Laser cutting is ideal for mass production as well as for complex projects that demand the highest repeatability.

Laser cleaning is an innovative process that enables the removal of contaminants and coatings from material surfaces quickly and without contact. The laser beam effectively eliminates rust, oxides, paint, and industrial residues without damaging the underlying structure. The process is safe, environmentally friendly, and does not require the use of chemicals or additional tools. Laser cleaning perfectly prepares components for further processing, increasing the efficiency of the entire production cycle.

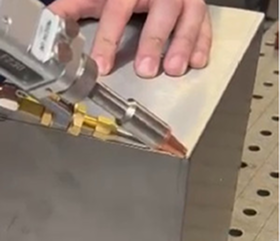

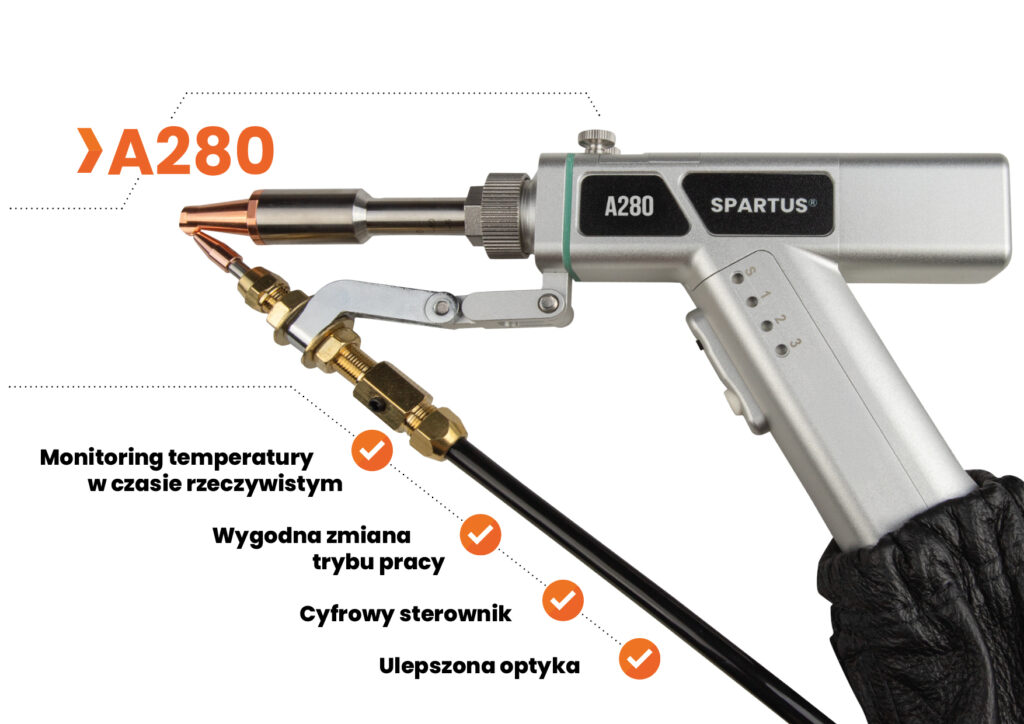

The A280 laser head is equipped with an advanced real-time temperature monitoring system. A flashing red warning light indicates overheating, while a steady light signals other types of alerts, ensuring full control over the device’s operation.

An independent mode-switch button allows for quick and convenient toggling between pre-programmed processes. The digital controller guarantees high resistance to interference as well as stable and reliable performance under all conditions.

Thanks to its improved optical design, the head ensures high weld quality, minimal distortions, and deep penetration, resulting in excellent welding outcomes.

A wire feeder is a key complement to a laser welder, responsible for the precise and stable delivery of filler material to the welding zone. Its use allows full control over the process, improves weld quality, and significantly increases production efficiency. Thanks to automated wire feeding, the operator can focus on supervising the entire process, which translates into consistency and reliability of results.

Depending on technological requirements and the nature of production, the user can choose between two solutions: a single or a dual wire feeder.

The SPARTUS single wire feeder is designed to ensure precise and stable delivery of welding wire to the welding zone. It is indispensable in applications that require the highest quality joints. It provides uniform and clean welds, which is crucial for productions with high standards. Its compact design guarantees easy integration with various models of Easy series laser welders.

The SPARTUS dual wire feeder was created for the most demanding industrial environments, where maximum efficiency and process flexibility are essential. Its innovative design enables the simultaneous use of two welding wires, which results in:

We invite you to take advantage of the opportunity to arrange a demonstration of SPARTUS laser welders anywhere in the country.

To schedule a presentation, please contact your welding equipment supplier. If the welder meets your expectations and you decide to purchase it, the demonstration will be completely free of charge. We encourage you to seize this unique opportunity to experience how our solutions can revolutionize your production processes.

The maximum number of products to compare is 4.

You can only compare products from the same category.

Would you like to remove all products from the comparison tool and add this one instead?